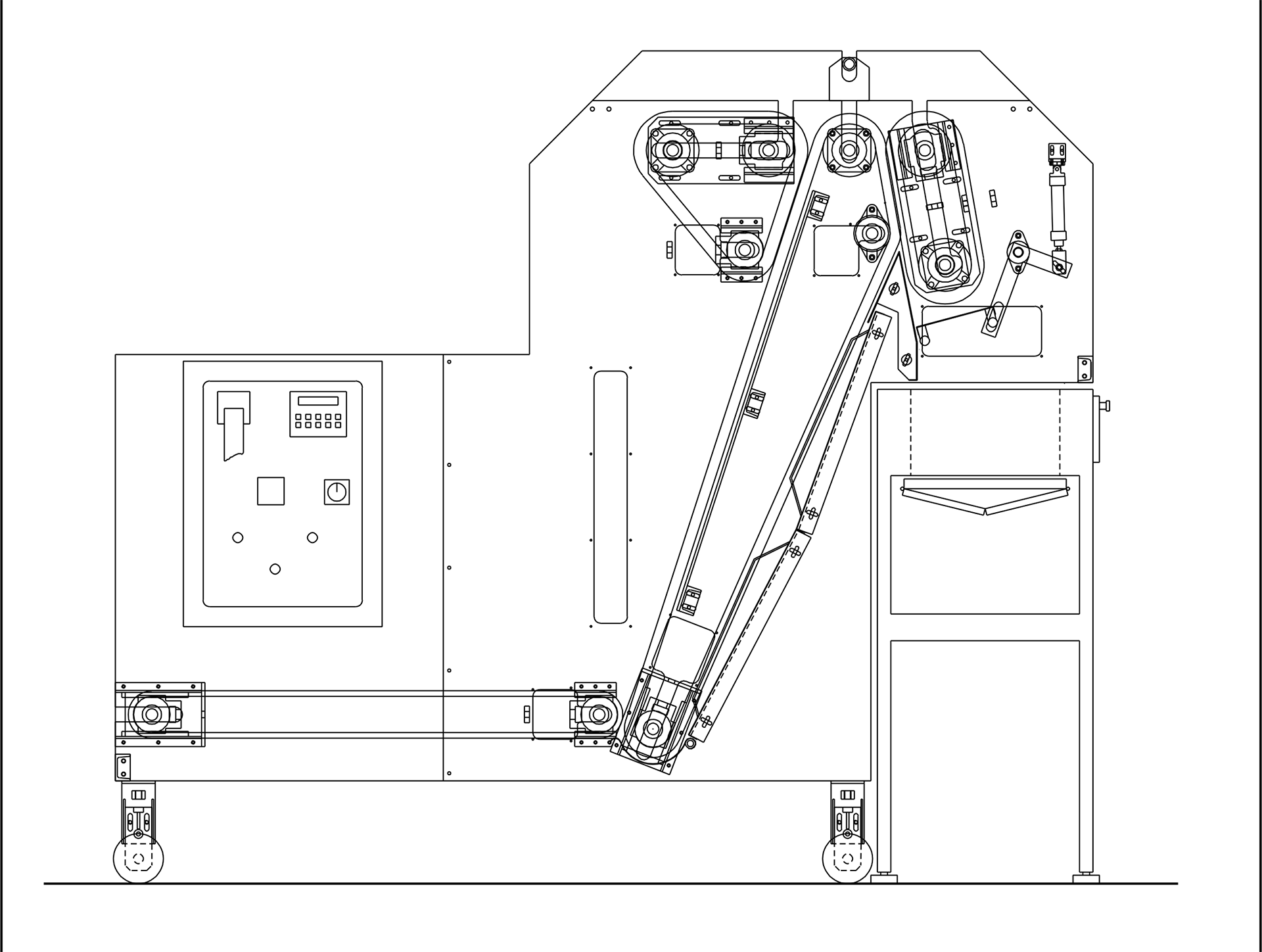

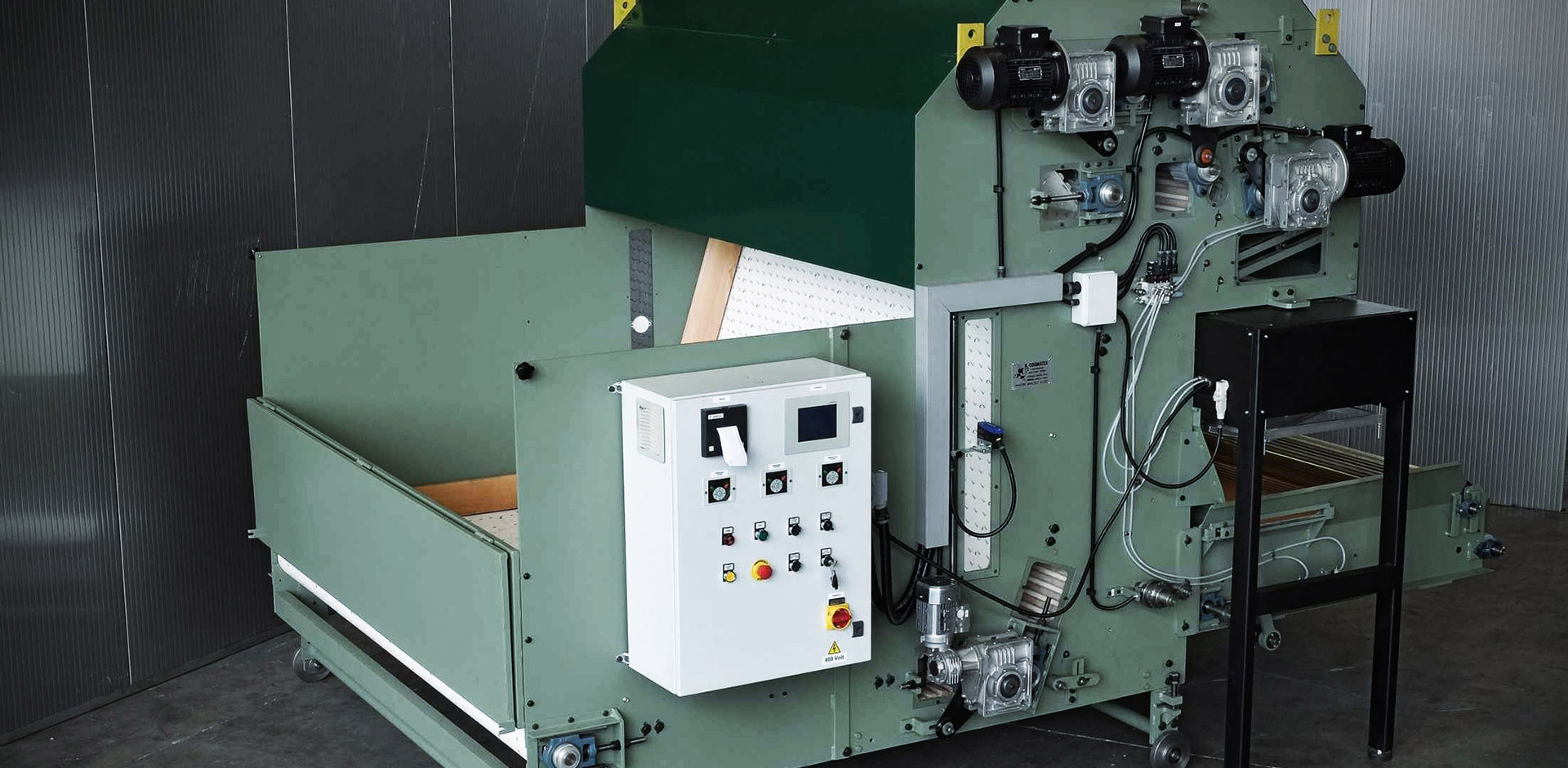

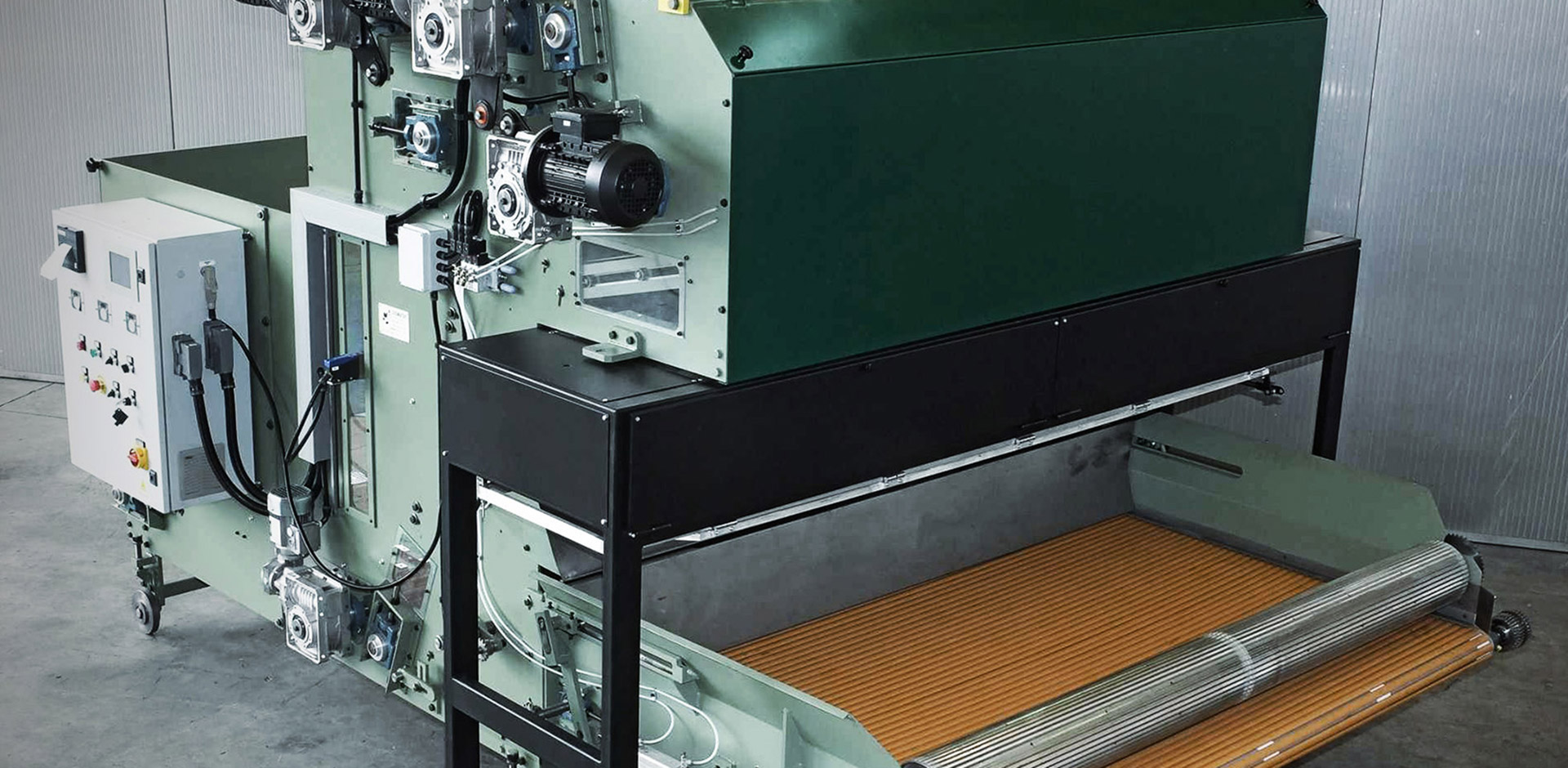

- made with different working widths from 1500 to 3000mm;

- feeding lattice made of PVC driven by a motoreducer with adjustable stop-and-go function;

- spiked lattice made of PVC, driven by a motor with inverter to allow variable speed according to the required weight;

- n.2 equalizing and detaching spiked lattices, with a particular positioning of steel points, interpenetrating that allow to feed very regularly the fibre material into the weighing pan, each one independently driven by motor with inverter to allow variable speed;

- electronic weighing pan with load-cell, detached from the hopper itself (to avoid being influenced by hopper vibrations), very sensible, with pneumatic opening motion;

- pneumatically driven lappet for stopping the flow of material inside the weighing pan once the drop weight is reached;

- electrical / electronic control panel with no.3 inverters, with drop weights and false-drop weights information, average, minimum and maximum weight value, CV value, etc. These data can be printed. The weighing system is measured by a computer type DTS equipped with a new software with self-learning cycles that automatically searches for the optimization between the weighing and speed times of the loading lattices of the hopper feeder. In that way the weighing phase, besides being very precise, is greatly simplified and avoids human mistakes brought by manual settings and adjustments of the machine.

Electronic hopper-feeder model TE