Reconditioned Products

Nuova Cosmatex modifies, refurbishes and up-dates existing machines

Cooperation with the most important Italian and overseas customers and the consequent transfer of experience between the end-user and our engineering expertise, coupled with the availability of very flexible and competent technical staff and the availability of large warehouses with various machine parts, have made NUOVA COSMATEX the most suitable company to be consulted in cases of requests for modifications on existing production lines.

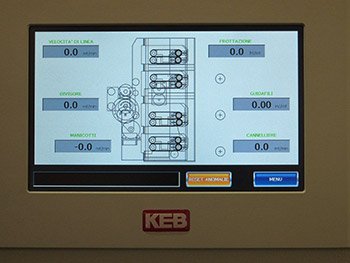

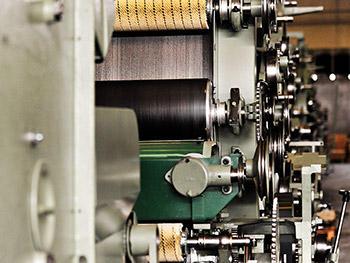

We can increase the production quantity or the quality of the finished products. We can install production controls, regularity controls, metallic parts electronic detectors, modification from one-tape-one-end to single endless tape condensers, as well as stepless weighing pans, electronic modification hopper-feeders, new calender rollers with tape width on request, electronic driving system, etc.

Such modifications can be carried out directly at the customer’s premises, so reducing transport costs, machine stop costs, and reducing overall logistical problems.

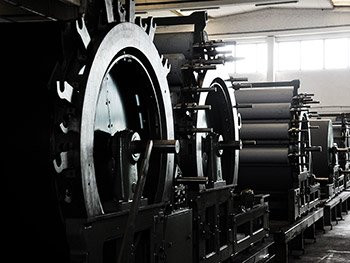

In the course of the 1980s and 1990s this sector became more and more important for our company. Thanks to our careful choice of quality second-hand machinery and to the possibility of carrying out bespoke modifications in an equipped workshop we propose ourselves as suppliers of complete second-hand lines for woollen and worsted spinning and nonwovens, technologically updated and at competitive prices.

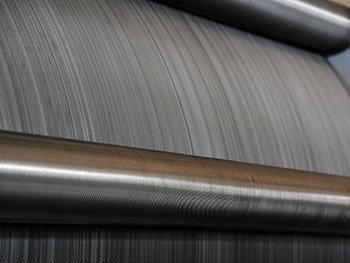

Normally the lines are composed partially of new machinery, and partially of second-hand ones, which are completely disassembled, checked and cleaned; broken or worn-out parts are replaced, then reassembly and tests on parts are carried out before shipment.

Such careful reconditioning work allows us to supply machinery with mechanical and technological guarantee on the end-product.