Innumerable ranges of items and colors have been created.

The single lots have been greatly reduced; consequently the efficiency of the production plants has decreased and the costs have grown up. The fashion trends are for garments lighter and lighter; that means finer and finer count yarn, but keeping a soft and pleasant “hand-touch”.

Our answers

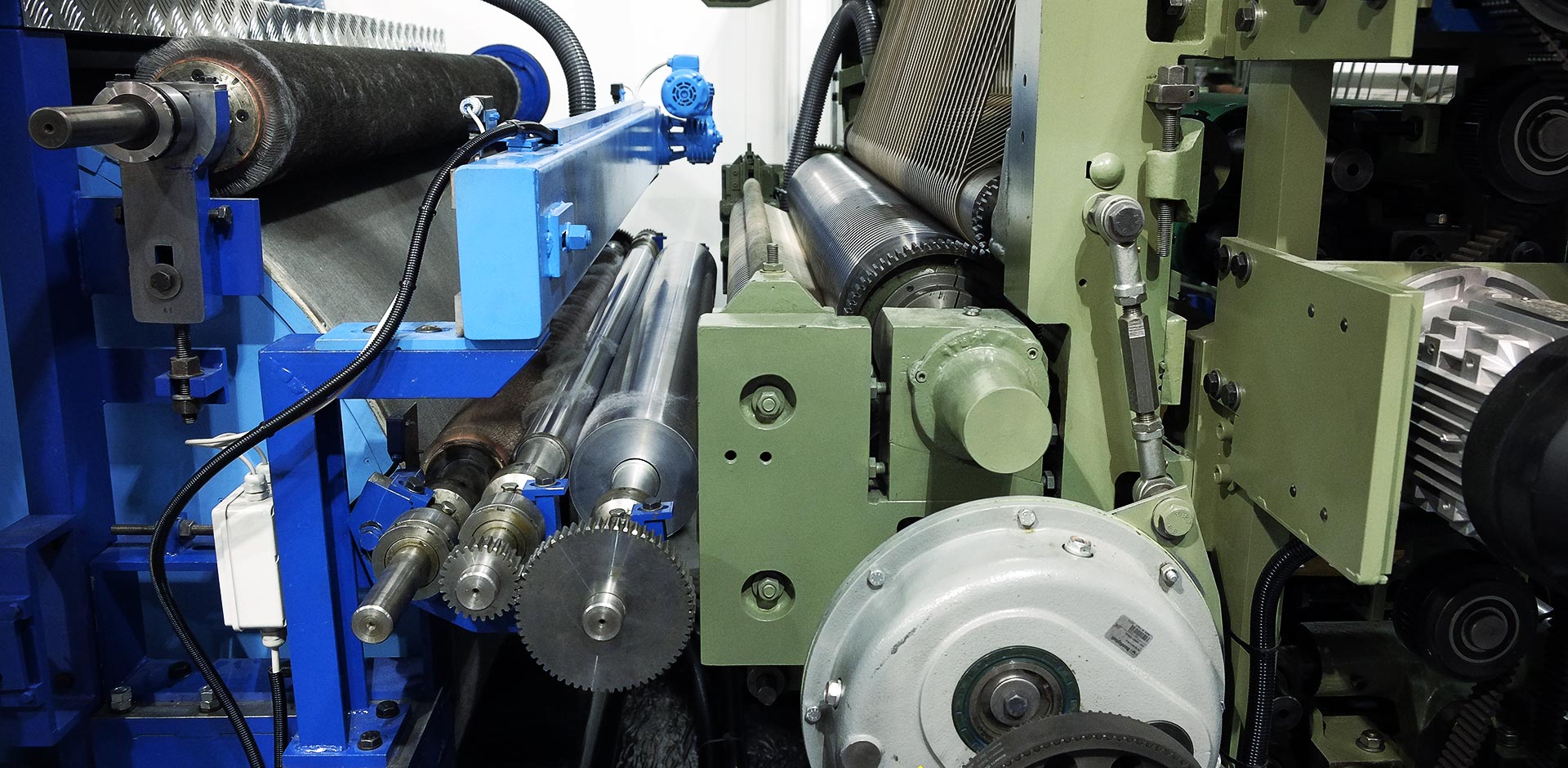

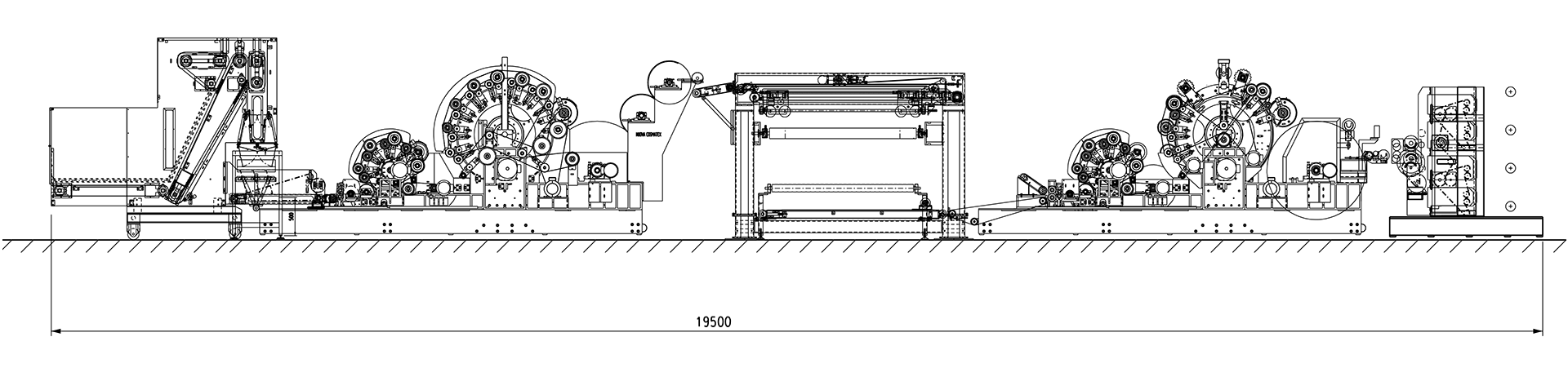

New carding system, with unique features, turned towards the environmental sustainability: ECOCARD

- It is narrow, 1500mm, and short, about 20mt. (it takes up less space, consequently it is possible to save energy for the workshop air conditioning system);

- It does not require the foundation pit (no masonry works are required);

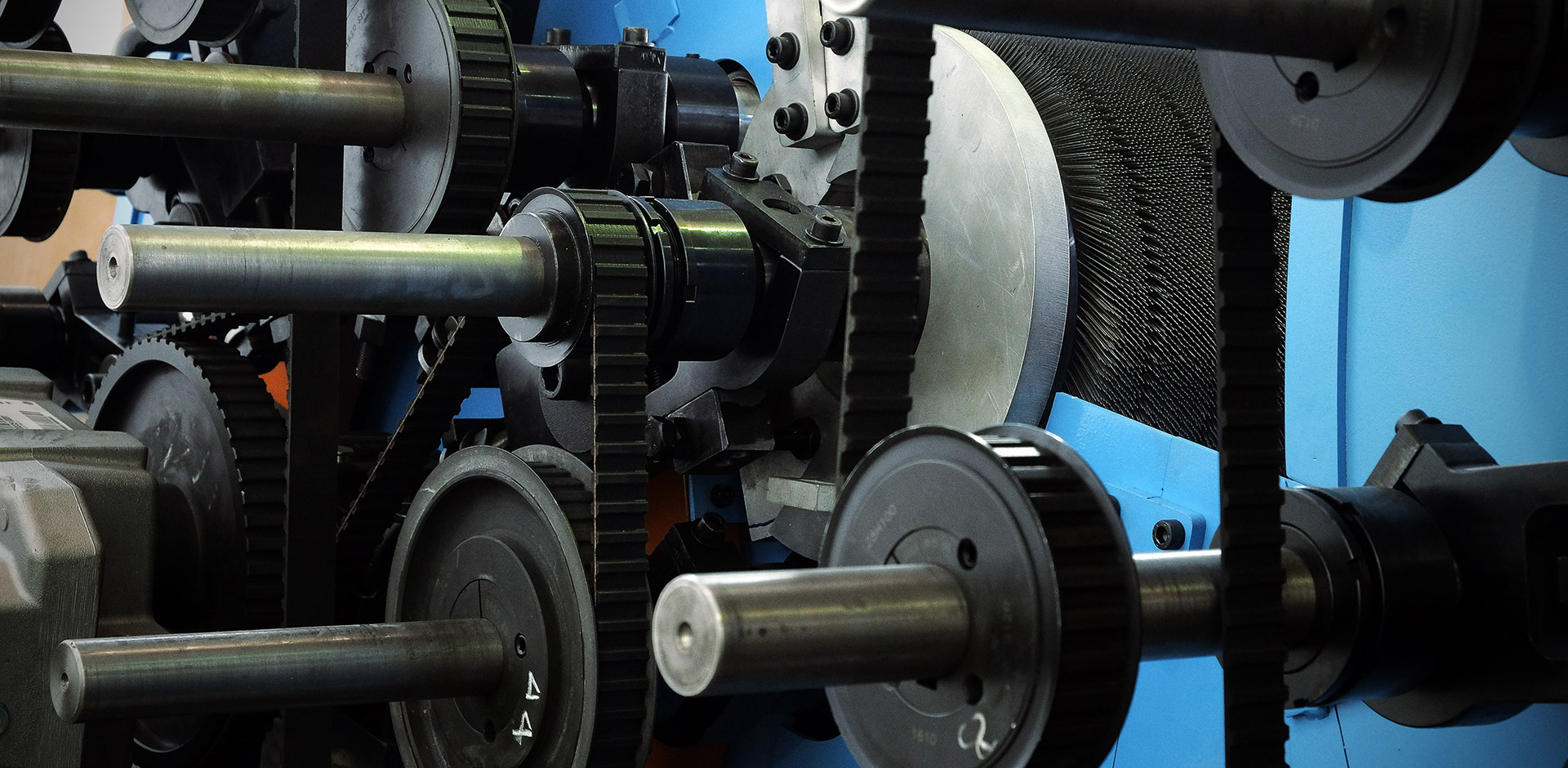

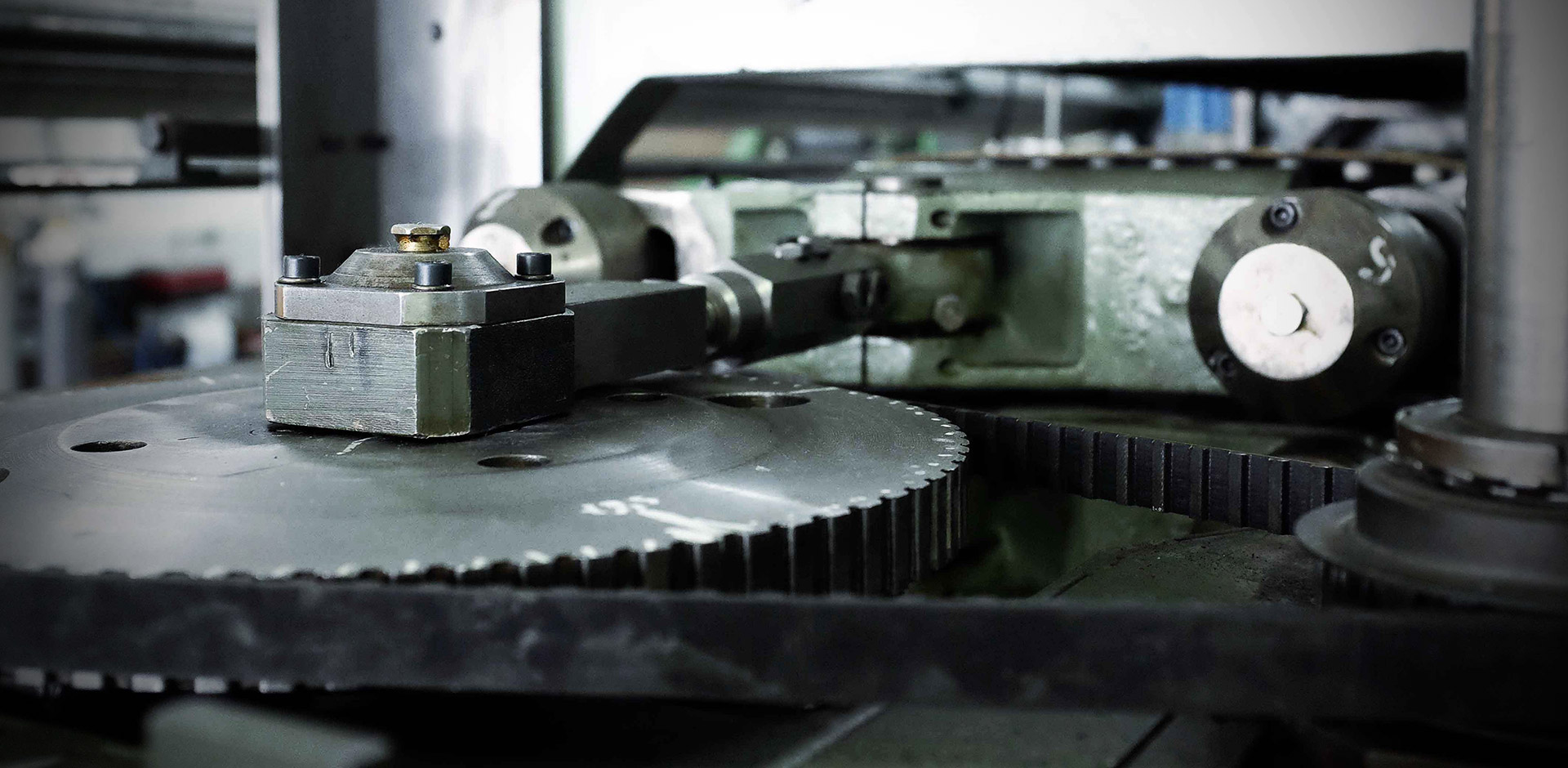

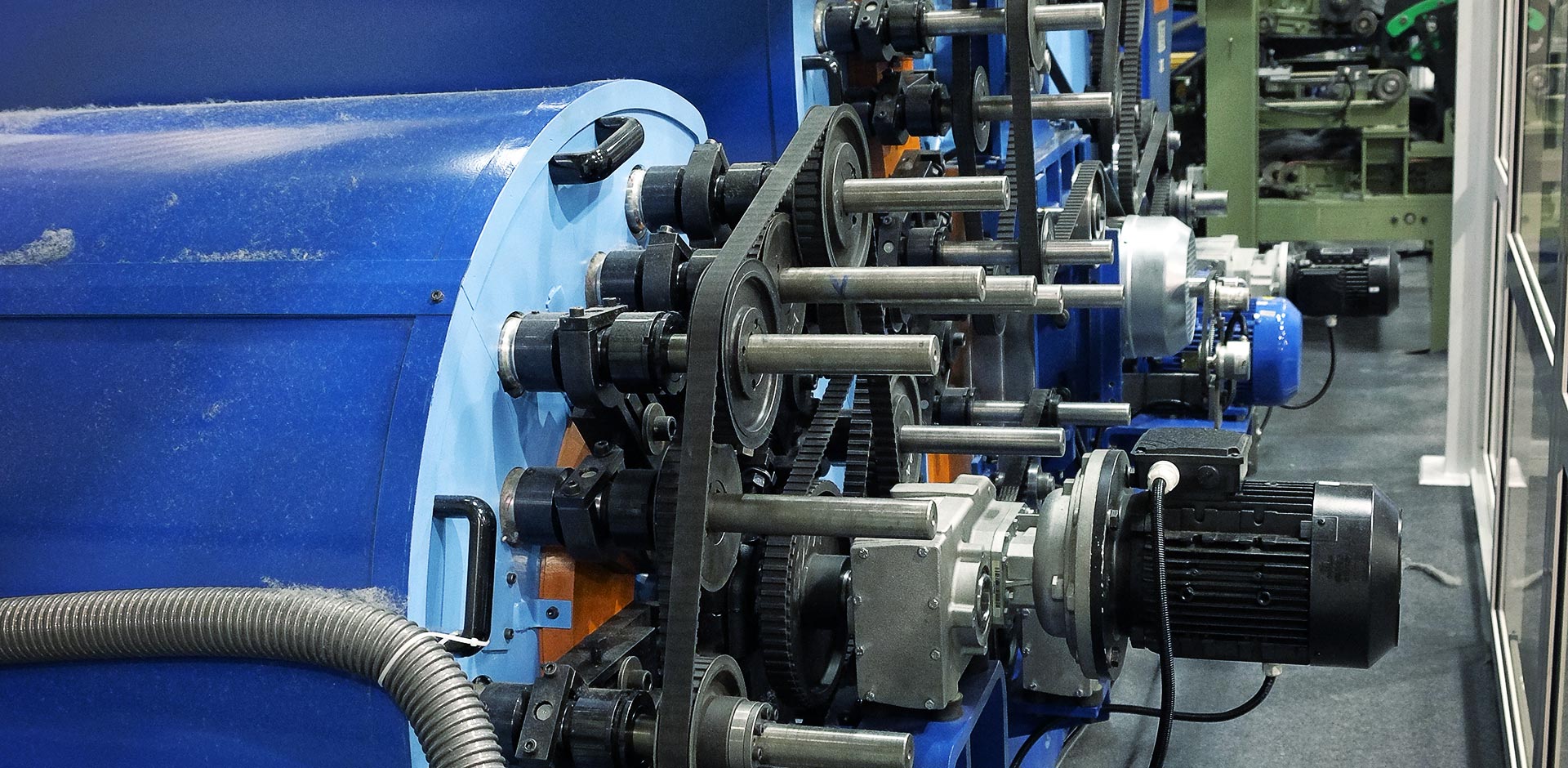

- It is made up of a smaller number of machines and moving elements, so it requires a lower energy consumption;

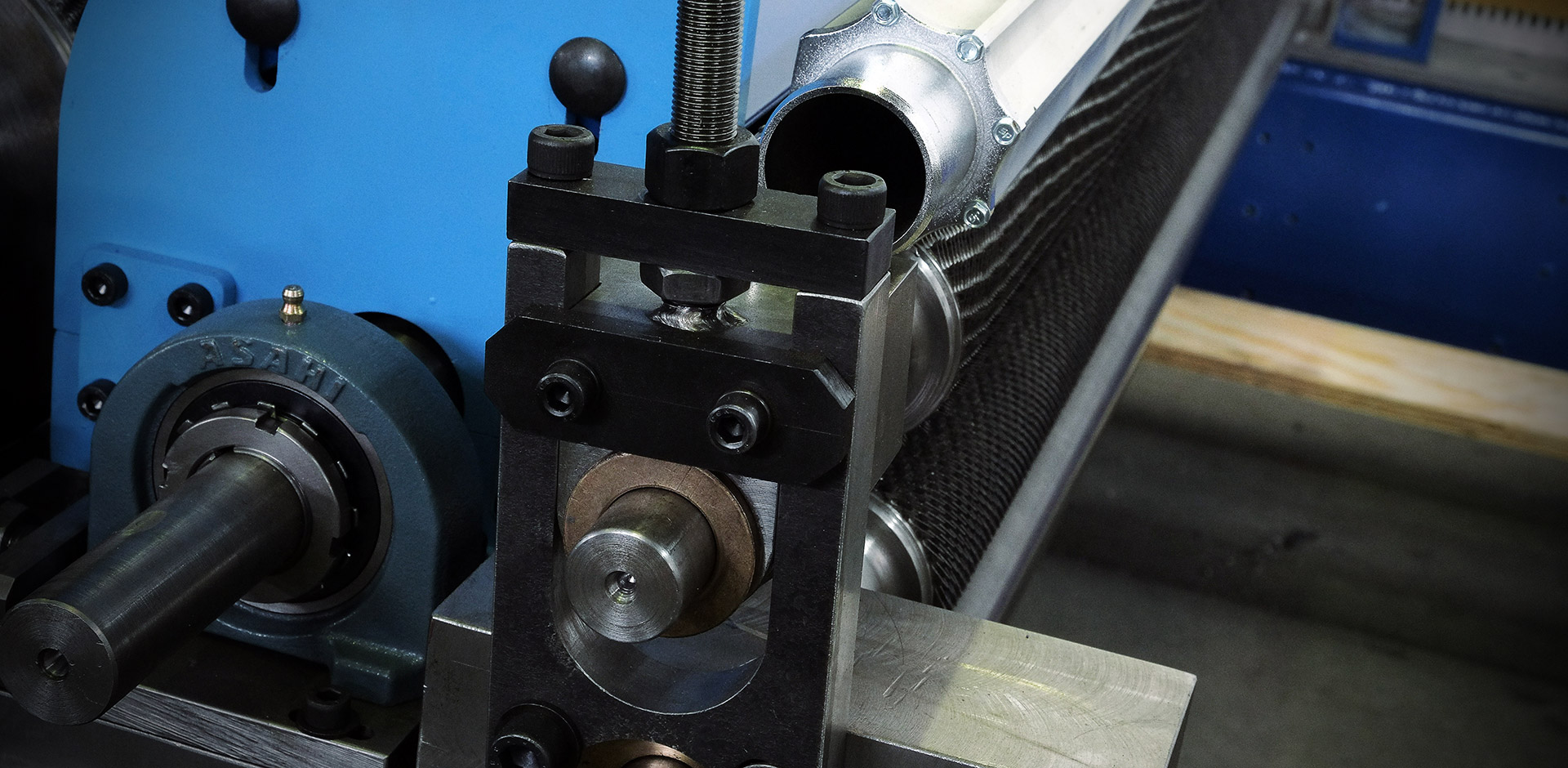

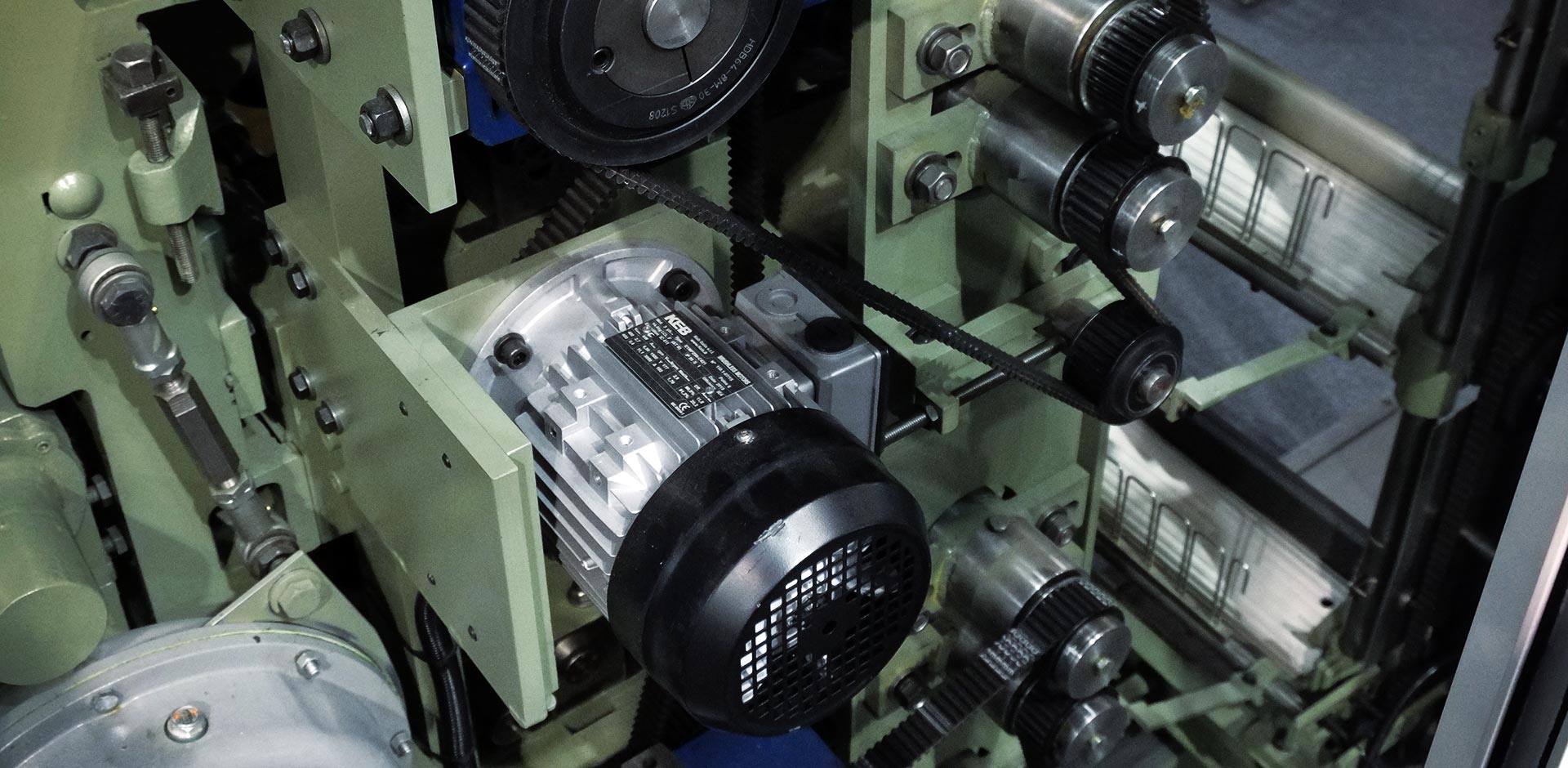

- Thanks to a new and more efficient driving system, it can carry out a high speed production;

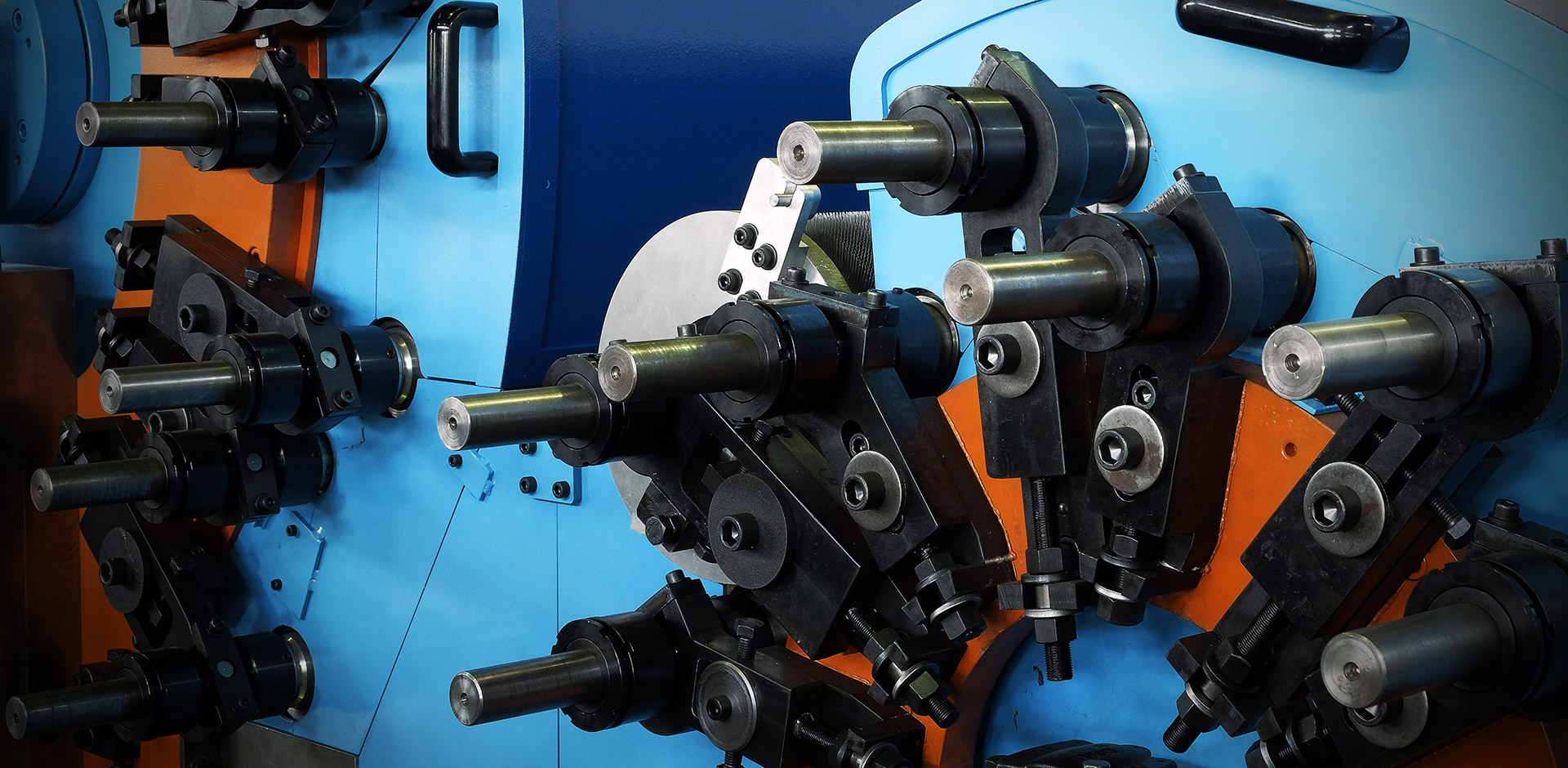

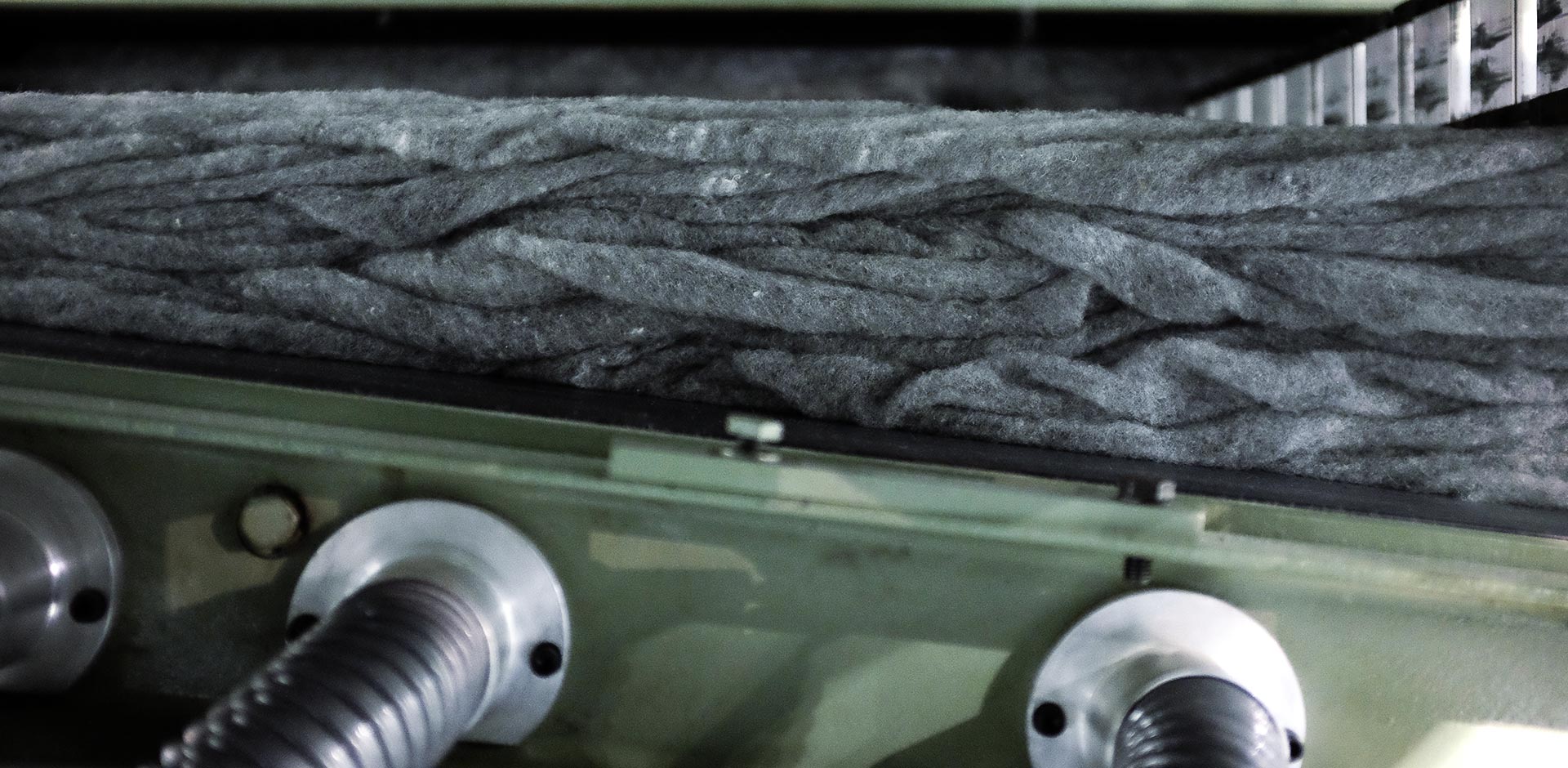

- Through the cooperation with the most important accessories manufacturers, the direction movement and the parallelization of the slubbing fibers has been reconsidered, to allow an intense drafting in the following spinning machines. Nevertheless this won’t cause the missing of the typical woolen yarn soft “hand-touch”;

- According to the current market requirements, split up in a great deal of items and colors, it is designed for a high efficiency and versatility with controls, speed and settings that can be adjusted by the operator panel;

- Thanks to a new fiber transport system and to its multi-layer effect, it is possible to reach blending results with different materials and/or different colors never reached before;