News

Automatic vacuum stripping device

Automatic vacuum stripping device

Device suitable for the automatic cleaning of the flexible card clothing of a carding set, of any working width. The device is composed as follow:

- adjustable stand for paralleling the tube with the card clothing

- high resistance and stiff aluminium profile frame;

- slinding of noozle-holding trolley on linear rails with ball bearing recircultion driving system for high precision and friction reduction;

- driving system of noozle-holding trolley with toothed belt and high resistance pulley, installed inside the cleaning device with aluminium movable safety band to avoid dust and fiber tangling;

- stepper driving motor with electronic sensor to measure automatically the useful cleaning stroke;

- electrical/electronic panel with start/stop buttons, plugs, sockets, driving unite with software, which allow different cleaning speed and various function and cleaning frequency;

- noozle, suitable fo the type of the fillet to be cleaned with locking unit.

Il progetto “LEANA”

Il progetto “LEANA”

Titolo "Sviluppo di nuovi prodotti tessili di fibre da foglie della pianta di ananas"

è realizzato grazie al co-finanziamento del POR FESR Piemonte 2014-2020

ASSE I - Azione I.1b.1.2

“Sostegno alle attività collaborative di R&S per lo sviluppo di nuove

tecnologie sostenibili, di nuovi prodotti e servizi”

Progetti collaborativi di ricerca e innovazione

Poli di Innovazione – Agenda Strategica di Ricerca 2018

Bando PRISM-E

Il progetto consiste nello sviluppo di nuovi materiali ecosostenibili per l’industria tessile dove le fibre cellulosiche sono sempre più richieste a livello internazionale

La fibra su cui si intende operare è quella ottenuta dalle foglie delle piante dell’ananas, che attualmente costituiscono uno scarto agricolo della coltivazione del frutto nei Paesi produttori.

In particolare sarà studiato con attenzione il pretrattamento della fibra grezza e le operazioni di cardatura che saranno ottimizzate in base alla lunghezza delle fibre e alle proprietà fisiche ed intrinseche per ottenere nastri adatti alla filatura (cardata ed open-end) da soli o miscelati con altre fibre cellulosiche naturali.

Le operazioni di tessitura saranno successivamente adattate in base al target di prodotto desiderato, inizialmente nell’ambito dei tessili per l’arredamento.

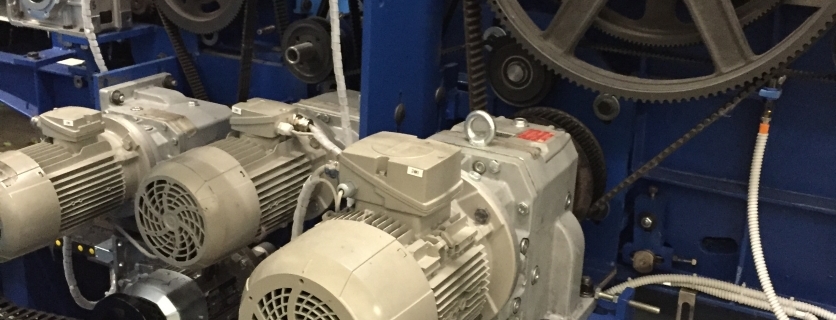

New way to think a carding sets

The Monteleone Group's innovation research in the carding field, both for traditional textiles and technical textiles, is going on.

New installations and innovative driving system provide higher flexibility, efficiency in changing lots and higher cleaning speed.

Two more lines were delivered to important Italian customers in the first half of the year.

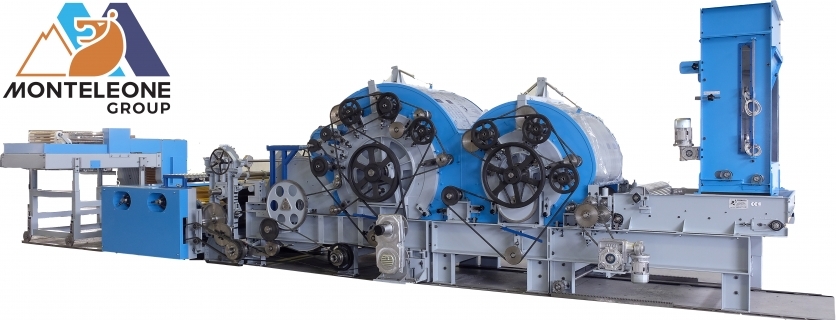

Second G-10 card unit

Monteleone Group delivered to a European company another G-10 card, working width 1000mm, for processing long staples fibers (wool, synthetic and blends), to meet the market requirements of small production lots and high use flexibility.

Card G-10

New Logo, new web site, new machine. The innovation is essential for those, who want to be leader on the market.

With the launch of the project named EcoCard, during the fair ITMA 2015 in Milan, Monteleone Group carried out great investments in technological innovation, revolutionizing the classic concept of textile machinery in the field of the woolen spinning.

The card G -10 with coiler, with working width 1000/1500mm, clothed with flexible card clothing and/or metallic wire, pursues the same goals.

Versatility is the surplus value of this machine. Using only two carding groups, it can process completely different fibers: from natural fibers, in particular the vegetable ones, until the most sophisticated synthetic or artificial fibers. It is possible to obtain well mixed slubbings with extremely interesting length diagrams, this according to the opinion of the customers, who tested the card G - 10.

The textile market is extremely large and diversified, so, if we focus only on the tradition and we create machinery only for knitting and weaving, we won’t be able to tape up the challenges imposed by the market.

Nowadays there is more and more interest on engineered and / or intelligent materials, polymers that are not existing in nature, suitable to create blends and/or variants with a low environmental impact

Monteleone Group, as a manufacturer of textile machinery and accessories, moves in this direction too and proposes to the customers innovative solutions, such as card G-10 to face the market changes.